"Monographs Quality" Lecture Hall Phase III Problem Analysis and Solution (8D Logic)

Release time:

2023-09-22 12:00

Source:

problem analysis and solution

(8D logic)

✦

"Monographs quality, prominent future!", Quality has always been one of the core competitiveness of Hechneng, and it is also the key to the long-term and stable development of Hechneng. No matter what kind of environment, the people of Huhe have been constantly learning, improving and breaking through!

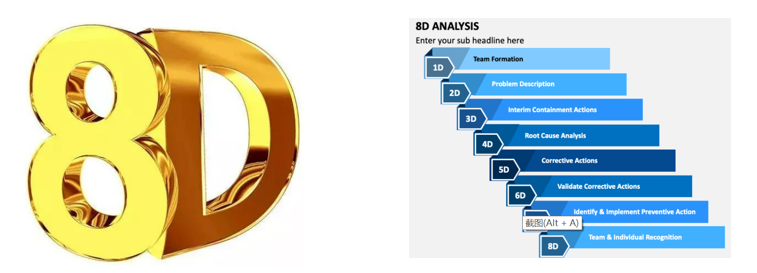

The third lesson of the quality class-"problem analysis and solution (8D logic)" carefully planned by the quality center of zhuhe group started recently. This course is still taught by Liu Biao, director of the group's quality center, for all students of the group. The 8D logic system in the subject of the course mainly expounds how to establish a group in the manufacturing process, describe the problem, take measures, analyze the causes, formulate countermeasures, verify and implement long-term countermeasures, prevent countermeasures and finally solve the problem.

✦

8D INTRODUCTION

8D also known as team-oriented problem solving method, 8D problem solving method (8D Problem Solving) is originated from Ford's method of dealing with problems, but also applies to the process capability index is lower than its due value when the problem solving.

Step 8D

At present, 8D has become a fixed and consensus standardized problem-solving step. Using 8D is to solve the problem, understand the problem, a comprehensive and true description of the problem is the top priority to solve the problem. What is the problem? The problem is the gap between reality and ideal. If you regard the problem as an iceberg, you can find the root of the problem, which is the real cause. Only by finding the true cause can we formulate countermeasures and measures to solve the problem fundamentally.

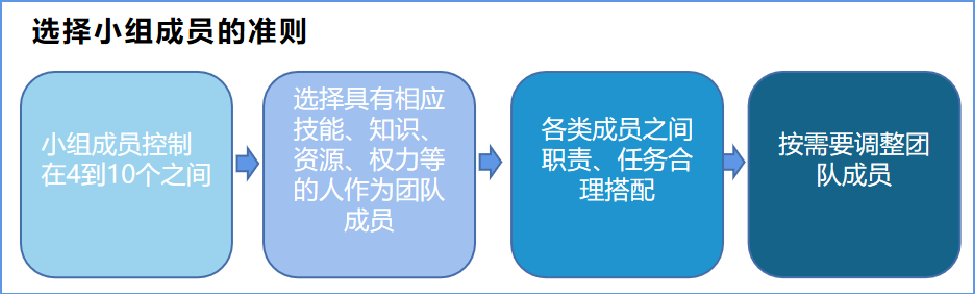

How to create a group

8D first find the problem, and then is the real first step to set up the team, is it not to find a few people to help? In fact, it is not so simple, the team needs to have a team leader, and then the team members should be the personnel of the relevant departments of the problem, as long as it is relevant should let everyone participate, so that the team members have a sense of belonging to the problem, a sense of belonging and a sense of mission and responsibility to deal with the problem. The team leader, team member, recorder and facilitator all perform their respective duties to make the team proceed smoothly.

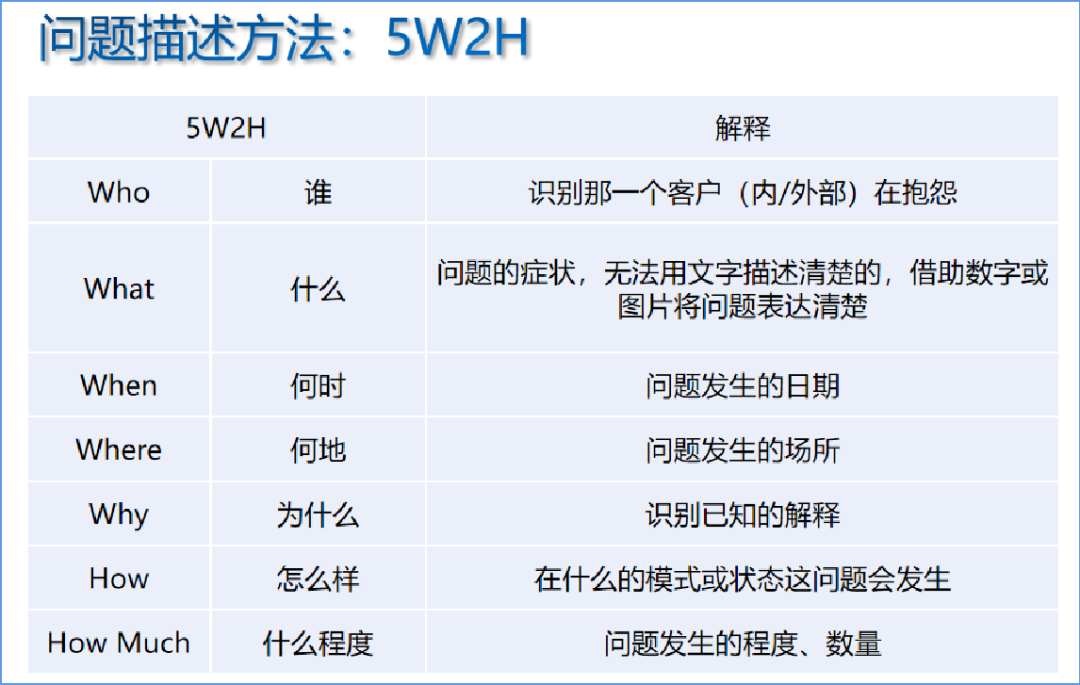

Problem Description

The second step is the problem description. This step is the key factor to solve the problem. It can be thoroughly described by 5W2H method. Here, the team members need to pool their wisdom and quantify the problems encountered as much as possible to clearly identify the people, things, times, places, why, how and how many involved.

take measures

The third step is to take measures: short-term corrective measures, long-term (permanent) corrective measures, to find the best choice of "measures", immediately make decisions and make implementation and records, synchronization needs to verify whether it is effective (DOE,PPM analysis, control chart, etc.).

Validation and implementation of long-term countermeasures

In the actual work to develop countermeasures must have a deadline for completion, develop a plan for the implementation of long-term countermeasures, the monitoring unit (internal quality or customer) on-site confirmation and verification of countermeasures have been implemented, and can eliminate the root cause. After it is determined that the long-term countermeasure verification is implemented, the temporary countermeasure can be abolished.

preventive countermeasures

Select preventive measures, verify effectiveness, based on facts and data, process data with statistical tools to draw corresponding conclusions, make decisions, implement and reformulate documents (organization, personnel, equipment, environment, materials, etc.) and continuously monitor to confirm that the root cause has been eliminated. Expand horizontally, modify the existing management system, operating system, working practices, design specifications, design drawings, etc. to prevent such problems and all similar problems from happening again. In long-term production, change/update precautions should be taken if necessary.

Select preventive measures, verify effectiveness, based on facts and data, process data with statistical tools to draw corresponding conclusions, make decisions, implement and reformulate documents (organization, personnel, equipment, environment, materials, etc.) and continuously monitor to confirm that the root cause has been eliminated. Expand horizontally, modify the existing management system, operating system, working practices, design specifications, design drawings, etc. to prevent such problems and all similar problems from happening again. In long-term production, change/update precautions should be taken if necessary.

Everything is done in advance, and nothing is done without advance.

Anticipate all possible crises and then make solutions our routine.

The last step

After class, the examination is routinely arranged to encourage everyone to put forward the problems observed in the work and answer them on the spot. Use the 8D step to select the best long-term countermeasures to solve the underlying problem, and also select the best long-term countermeasures to control the impact of the root cause. At the same time, I also congratulate each member of the group and affirm the efforts of the members of the group.

We will carry out a series of courses on "quality of monographs" and implement the group's quality policy of "seeing small works, specializing in special innovation, full participation, green production and sustainable development", so as to help enterprises develop with high quality, constantly provide customers with better products and services, and create greater value.

We will carry out a series of courses on "quality of monographs" and implement the group's quality policy of "seeing small works, specializing in special innovation, full participation, green production and sustainable development", so as to help enterprises develop with high quality, constantly provide customers with better products and services, and create greater value.

Next Page

Related News